ENG5316 Advanced Ultrasonics

Hello, dear friend, you can consult us at any time if you have any questions, add WeChat: daixieit

Advanced Ultrasonics ENG5316

Coursework Project Descriptions

Bubble modelling (Paul Prentice)

Cavitation bubbles are challenging to investigate experimentally. As such, the scientific literature is rather dominated by simulations of bubble dynamics, via a number of models, with various adaptations to account for a wide range of conditions (including ultrasonic driving, hydrodynamic environments and stabilising shells – in the case of contrast agent microbubble).

The most established model is based on the Rayleigh-Plesset (R-P) equation. This is a non-linear ordinary differential equation relating bubble dynamics to liquid properties and pressure terms.

Students taking this project will solve the R-P equation (in Matlab, or equivalent). Options for investigation include parametric analysis (of the influence of viscosity, for example), non-linear bubble response, or comparison to experimental observations (undertaken in the Cavitation Research Laboratory).

Learning outcomes:

• Bubble theory & simulations

• Parametric analysis

• Non-linear bubble dynamics

• Coding experience

• Cavitation and applications

Further reading:

The Acoustic Bubble, T. G. Leighton (Academic London, 1994) Lauterborn & Kurz, Physics of bubble oscillations, Rep. Prog. Phys., 73 106501, 2010

Measuring non-linear pressure waveforms (Paul Prentice)

Measurement of a linear ultrasonic signal is relatively trivial. Detection is undertaken with an appropriate hydrophone, at the relevant position relative to the source. Application of a calibration coefficient – at a single value of frequency – to the voltage output from the hydrophone, retrieves the pressure measurements.

A non-linear waveform, however, will have content across multiple frequency values. Assessment of the non-linear content is good scientific practice and critical for many applications, with tissue absorption being highly frequency dependent, for example.

This project will explore concepts and techniques for handling non-linear pressure waveforms. Experimental measurements will be provided, along with complex calibration data (supplied by the National Physical Laboratory) for the detecting hydrophone. Students are expected to assess the frequency content within the measurements and investigate how the calibration data should be applied.

Learning outcomes:

• An understanding non-linear ultrasound

• Assessing frequency content

• Hydrophone calibration and uncertainties

• Hydrophone deconvolution

• Appropriate reporting of nonlinear measurements

Relevant papers:

[1] L. Yusuf, M. Symes & P. Prentice 2021. Characterising the cavitation activity generated by an ultrasonic horn at varying tip-vibration amplitudes. Ultrasonics Sonochemistry, 70 105273.

[2] J. H. Song, A. Moldovan & P. Prentice 2019. Non-linear acoustic emissions from therapeutically driven contrast agent microbubbles. Ultrasound in Medicine & Biology 45(8), pp 2188-2204.

Simulating effective frequency response (Andrew Feeney)

Relevant Research Paper: Dixon, S., Kang, L., Ginestier, M., Wells, C., Rowlands, G. and Feeney, A., 2017. The electro-mechanical behaviour of flexural ultrasonic transducers. Applied Physics Letters, 110(22), p.223502.

Ultrasonic sensors are embedded in a wide range of industrial measurement systems, for non- destructive evaluation, flow measurement for gases and liquids, and proximity sensing for robotic or automotive applications. Ultrasonic sensors for industrial applications are often capacitive or piezoelectric micromachined ultrasonic transducers (cMUT and pMUT respectively). However, more recently there has been a drive to optimise the performance of the flexural ultrasonic transducer (FUT), a configuration which does not require acoustic impedance matching to its environment.

Typically, such flexural-based ultrasonic transducers rely on the bending of a compliant plate, whose vibration modes are generated through an excitation voltage to a piezoelectric material attached to this plate. They do not operate on the conventional through-thickness or radial mode principles, instead being analogous to an edge-clamped plate, where the vibration response of this plate can be assumed to dominate, thus governing the dynamics of the transducer. To this end, Leissa’stheory of vibrating plates has direct relevance, where fundamental and higher order modes can be predicted with confidence.

In this project, your challenge is to define suitable design and fabrication parameters for a 40 kHz flexural ultrasonic transducer for proximity measurement in ambient air. Secondly, in away you see fit on MATLAB or otherwise, you will find away to simulate the effective frequency response of the transducer for an arbitrary excitation, using the governing relationships associated with edge-clamped plates, where a clear distinction between resonant and off-resonance responses is demonstrated.

Learning outcomes:

• An introduction to measurement / sensing with ultrasonic transducers

• Design and fabrication considerations for industrial ultrasonic sensors

• Appropriate use of finite element methods

• Extension of Leissa’s theory to ultrasonic sensors using MATLAB or equivalent

• Understand implications for deployment in different industrial environments

Ultrasonic compaction and fluidisation (Andrew Feeney)

Relevant Research Paper: Feeney, A., Sikaneta, S., Harkness, P. and Lucas, M., 2017. Ultrasonic compaction of granular geological materials. Ultrasonics, 76, pp.136-144.

In principle, fluidisation of granular materials in the context of ultrasonic technology is one known consequence of the drive to enhance the compaction or consolidation of granular materials, for the purposes of manufacturing specific mechanical components or medications. This is often performed to enhance the strength of these products, and as an example, ultrasonics has already been successfully applied in the strengthening of amalgams for dentistry.

Ultrasonic compaction causes areorientation of particles towards a threshold in compaction pressure, after which particles are crushed towards a state of enhanced packing. In the former stage, this reorientation can render particles to behave together more like a fluid. In the latter stage, the particles undergo physical compaction and crushing.

In this project, you will investigate the critical parameters for enhancing the consolidation of different granular materials using ultrasonics, propose a relationship or analytical representation of what happens to vibrating particles in a compaction process, and use real experimental data to derive links between ultrasonic amplitude, strain rate in a sample, and the characteristics of the material being consolidated. It would be particularly interesting to note your perspectives on the compaction modulus, that which is derived from published strain-pressure relationships.

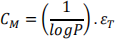

As a hint to help, one viable way of quantifying compaction modulus can be:

Where CM is compaction modulus (Pa-1), P is pressure (Pa), and εT is true strain.

Learning outcomes:

. Ultrasonic compaction

. Ultrasonic fluidisation

. Interpretation of measurement data

. Linking experiments with models

. Data analysis

2024-02-07