MATS15301 MICROSTRUCTURE OF MATERIALS

Hello, dear friend, you can consult us at any time if you have any questions, add WeChat: daixieit

MATS15301

MICROSTRUCTURE OF MATERIALS

24 January 2023

SECTION A

Answer All Questions from this section

1.

(a) A significant difference in the typical microstructure of ceramics compared to metals, is the presence of porosity.

(i) What process typically limits the removal of porosity in ceramics. (2 marks)

(ii) Porosity often limits the use of ceramics for some applications. Explain why porosity is difficult to eliminate and how the addition of MgO as a dopant during processing can enable the use of alumina in sodium streetlights. (8 marks)

(b) Describe three types of point defects that occur in crystal structures. (3 marks)

(c) Discuss how point defects affect diffusion in crystalline metals/ceramics. (7 marks)

SECTION B

Answer THREE questions from this section

2. The properties of a material will dictate which processing tools are

suitable for producing a final component and how its microstructure can be optimised.

(a) For metals and ceramics:

(i) What are two differences in the typical properties of metals and ceramics that define their processing routes? (2 marks)

(ii) With the aid of a fully labelled sketch, plot the typical responses of each during a uniaxial tensile test. (3 marks)

(iii) Suggest an appropriate processing method for each,

explaining the how the differences in mechanical response determine how each material is shaped into a final product. (6 marks)

(iv) Once formed into a shape, ceramics usually require an

additional process to give them their final properties. Name this process and explain what it does. (5 marks)

(b) Certain polymers exhibit a glass transition temperature. Explain why this property is important and how it can be exploited during processing. (4 marks)

3. Thermomechanical processing and chemical additions are two methods typically used to provide strengthening in Al alloys.

(a) Which of these methods typically provides the highest level of strengthening and why? (2 marks)

(b) For alloys where thermomechanical processing is used:

(i) Describe how the microstructure changes during deformation. (3 marks)

(ii) Explain how these changes during deformation affect the mechanical properties. (3 marks)

(iii) Describe the two ways a deformed microstructure can

evolve when a heat treatment is applied after deformation and the impact of each on the properties of the material. (6 marks)

(c) For Al alloys where chemical additions are used to provide

strengthening, describe the purpose of the following stages of processing:

(i) Initial heat-treatment at a relatively high temperature. (2 marks)

(ii) Rapid cooling after initial high temperature treatment. (2 marks)

(iii) A final heat treatment at a moderate temperature. (2 marks)

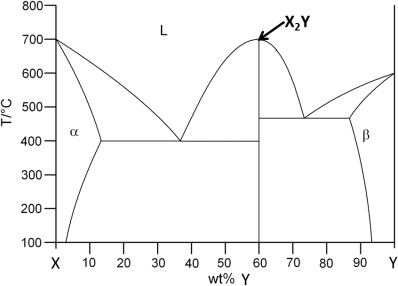

4. Figure 1 shows the phase diagram for a binary alloy of X and Y.

Figure 1

(a) For this phase diagram (Figure 1), describe all congruent phase transformation(s). (3 marks)

(b) For the alloy containing 20 wt.%Y, calculate the weight fraction of the phase(s) present in the alloy at a temperature of 500。C. (5 marks)

(c) For an alloy that contains 20 wt.%Y on cooling from its molten

state to room temperature, sketch the cooling curve (temperature- time response). Explain the features on the cooling curve and describe the associated microstructure changes (12 marks)

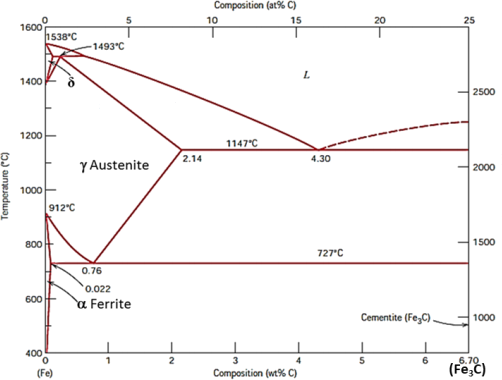

5. Figure 2 shows the section of the Fe-C phase diagram relevant to steels.

Figure 2 Fe-C phase diagram

(a) For non-equilibrium cooling of a steel that contains 1.2 wt.% C from its molten state to 1150 °C, sketch the microstructure of the steel at 1150°C and explain how the microstructural features are formed. (10 marks)

(b) Describe (with the help of schematic sketches) the

microstructural changes that take place in the steel that contains 1.2 wt.% C during cooling under equilibrium conditions from 1150 °C to 600 °C. (10 marks)

2024-01-24