MGMT2017 Supply Chain Decision Analytics

Hello, dear friend, you can consult us at any time if you have any questions, add WeChat: daixieit

MGMT2017 Supply Chain Decision Analytics

Trimester 3A–2023, Singapore

Group Assignment

Format: Business Report

Due date: (Friday, 19th January 2024, 11:59 PM)

Submission: Online through Turnitin

Marks: %35 marks

1 Objective

This assessment item relates to the course learning outcomes 2, 4, and 5 as stated in the unit outline.

2 Scenario

2.1 Description of Case Study

BERLIN BREWERY is a Berlin beer brand well-known for its small, traditional, handmade beer. Currently, they have one brewery (factory) and one DC in Berlin. Although they have been in business a short time, they already have 50 customers in eight countries. Nevertheless, they face several problems which need to be solved. On the one hand, the German beer market, which is the primary market with the highest sales for BERLIN BREWERY, can be characterized as a mature market with strong prices and pressure from competition. A sales crisis has been going on for years and competition is intensifying as a result of consolidation processes implemented by international brewing companies. To expand their distribution network and reduce costs by inventory management improvements, a simulation and optimization analysis must be performed to evaluate their current SC performance and develop suggestions for its improvement.

To provide context, an overview of the German and international beer market will be explained, and the relevant technical details of the BERLIN BREWERY and its SC presented. Next the current problem will be described, followed by developments of the GFA, NO, and Simulation alongside the respective results. Finally, recommendations for management need is given based on the computational results.

Beer is an alcoholic and carbonated beverage which is made by fermenting water, malt, and hops. The production of beer can be traced back to the farmers who lived in the 4th millennium BC during the Babylonian and pharaonic times. In Europe, the addition of hop to water only became generally valid in the 14th century. In the early Middle Ages, beer was brewed primarily in monasteries. Particularly in northern Germany, the top-fermented brewing industry flourished. After the Thirty Years’ War, Bavaria gradually came to the fore as a beer country. To save the purity and tradition of beer, the Bavarian dukes Albrecht IV and William IV regulated the raw materials with strict purity laws. According to these laws, only barley, hops and water could be used to make beer. The purity requirement of 1516 is the oldest, still valid food legislation in the world (o.V.2017).

The German brewing tradition enjoys a prestigious reputation worldwide. According to the German Brwers’ Federation (o.V.2017), there were around 5,000 beer brands in Germany at the beginning of 2015 and over 6,000 in 2017. The trend is rising, although consumption is decreasing.

The market for beer products and the German brewing industry are characterized by strong prices and competition. As mentioned, a sales crisis has been going on for years and the competition is intensifying because of consolidation processes implemented by international brewing companies.

The SC of a brewery is highly complex. First, essential ingredients (hops, malt, yeast, and water) and extra ingredients have to be shipped to the brewery. Shipping hops is particularly complex as the product is very sensitive: moisture, heat, and oxygen reduce its brewing value over time. As a result, hops must be stored between -2 ![]() and +3

and +3 ![]() Celsius. After the brewing process, the young beer is stored in tanks at a temperature of 1

Celsius. After the brewing process, the young beer is stored in tanks at a temperature of 1 ![]() to 2

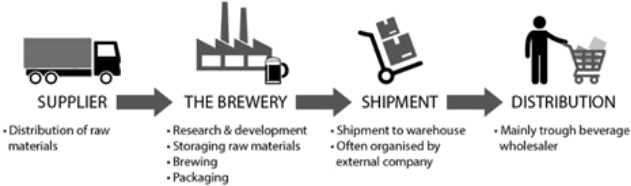

to 2 ![]() Celsius for a length of time between three weeks and three months. In this time, the beer ferments and gets its characteristic colour. In the final steps, the beer is filtered, bottled, and labelled (Plank, 2013). Figure 1 summarizes the logistics process of the craft beer industry.

Celsius for a length of time between three weeks and three months. In this time, the beer ferments and gets its characteristic colour. In the final steps, the beer is filtered, bottled, and labelled (Plank, 2013). Figure 1 summarizes the logistics process of the craft beer industry.

Figure 1: Logistics process of the craft beer industry

Warehousing, picking, and loading are carried usually out by company employees, but this depends on size and internal factors for each company. Some companies set up their own service companies for in- house logistics, but most breweries engage external companies for sorting empties, cleaning empties, and the cleaning of the plant. Compared to other industries, the distribution of beer is diversified as many di↵erent channels have to be covered. These include the classic food retail trade, beverage disposal markets, food discounters, petrol stations, and gastronomy. However, the importance of di↵erent distribution channels has changed in recent years. Food retailers (especially discounters) have gained more importance in the brewing industry, while the importance of gastronomy has declined. In general, all channels receive the beer either directly from the breweries (it’s possible that a third-party-logistics provider takes care of transportation) or through a beverage wholesaler.

2.2 Problem Statement

Currently, the BERLIN BREWERY’s Brewhouse consists of 5 tanks which have a total capacity of 20hl. Assuming that demand for its beer is rising, the BERLIN BREWERY has the option to expand its Brewhouse with more tanks. The whole process from the original brewing to the finished product requires between four to six weeks depending on how long each type of beer must be stored. As the location of production in Berlin is small, all beer produced is stored in the only DC in Berlin. An external service provider takes care of all logistical requirements. Currently, most of the beer BERLIN BREWERY sells is sold in Berlin, though the craft beer is also sold to wholesalers all over Germany. Since 2018, customer locations include Switzerland, Austria, Sweden, Norway, France, Italy, and Spain. BERLIN BREWERY collaborates with three suppliers in Germany who deliver empty beer bottles in crates, as well as the hops and malt. Empty bottles in crates are delivered from a location close to Nuremberg, the hops come from Koblenz, and malt is delivered by a supplier from a location close to Dresden. BERLIN BREWERY’s current sales’figures and further financial figures, which are important for the analysis, are summarized in the next step. One-o↵ acquisition costs for the brewing equipment is $300,000. Moreover, maintenance costs (including energy and electricity) for the location of the factory are $80,000 per month or $2,630 per day.

Assuming that one beer crate consists of 20 bottles, the whole cost for one crate is $10. Note that in the anyLogistix model, we consider a product “Beer” which is equivalent to one beer crate.

The costs of the product “Beer” can be broken down as follows in Table 1.

Table 1: Bill of materials (BOM), based on information of BERLIN BREWERY

Table 1 depicts the BOM (Bill-of-Materials) for the product “Beer” which consists of 1 piece of Hops, 1 piece of Malt and 1 piece of Crate.

Carrying costs, which include warehousing costs, handling inside inventory, and inventory costs, are estimated to be $0.005 per beer crate ($0.2 per pallet) per day. The transportation from the BERLIN BREWERY factory to the DCs are calculated as product-distance based transport and costs are $0.00175 per km/beer crate ($0.07 per pallet). The transport from the three suppliers to the BERLIN BREWERY factory is paid by suppliers. Inbound and outbound costs are shipment processing costs. Outbound costs are assumed to be $0.66 per beer crate ($26.40 per pallet) and inbound costs are $1 per crate ($40 per pallet). Hops and malt are delivered in a one-kilogram packaging unit: one pallet of malt or hops equals 40 packaging units.

BERLIN BREWERY wishes to expand its sales and work as efficiently as possible to increase profit. To reach these goals, several problems must be overcome: as mentioned in the first section, beer consumption in Germany, BERLIN BREWERY’s main market, is decreasing and the market as a whole is highly competitive. The German beer market is a mature, nearly saturated market. Two potential solutions exist: expansion into other countries or increased sales to existing customers. These options instigate further challenges as BERLIN BREWERY has only one DC in Berlin. Long routes and long delivery times to individual customers are the main problems. Because of the long routes, BERLIN BREWERY can respond only relatively inflexible to spontaneous requests and a high number of unnecessary routes might be taken. There is also the risk of man-made or natural disruptions which can influence service quality (e.g. a storm destroys DC).

In sum, the goal of BERLIN BREWERY is to expand their distribution network, serve their customers as efficiently and satisfyingly as possible, raise their sales numbers, and increase profit. This is possible by optimizing their SC: an optimal number of DCs as well as good locations for these DCs must be found to save as much logistics costs as possible. Loss of quality and delivery problems should be avoided.

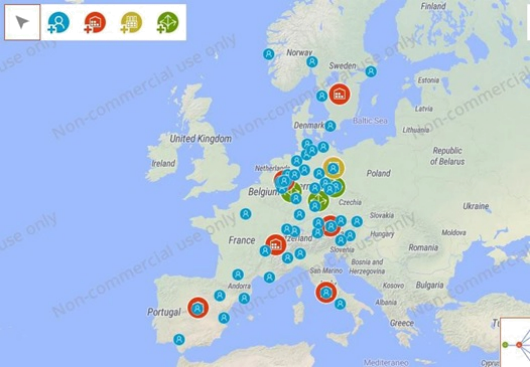

Fig. 2 depicts the current situation. Production is in the centre of Berlin and the raw ingredients are shipped by truck directly from Dresden, Nuremberg, and Koblenz. To store as little as possible, raw materials are delivered on demand and used directly (JIT- just-in-time) for the production. The beer is delivered to 50 customers all over Europe.

Figure 2: Current network of BERLIN BREWERY

To provide a better understanding of the circumstances, a few assumptions are made:

![]() All prices and costs are shown and calculated in $ .

All prices and costs are shown and calculated in $ .

![]() All processes are considered in terms of (beer) crates or pallet specifications, rather than bottles. This is because BERLIN BREWERY sells their beer only in whole crates, and these terms help to simplify the model. In one beer crate there are always 20 bottles of beer, which have 0.33 liters of content per bottle (6.6 liters per crate).

All processes are considered in terms of (beer) crates or pallet specifications, rather than bottles. This is because BERLIN BREWERY sells their beer only in whole crates, and these terms help to simplify the model. In one beer crate there are always 20 bottles of beer, which have 0.33 liters of content per bottle (6.6 liters per crate).

![]() 1 pallet = 40 beer crates = 800 beer bottles

1 pallet = 40 beer crates = 800 beer bottles

![]() The recycling deposit on bottles is not considered.

The recycling deposit on bottles is not considered.

![]() Transportation costs from the factory to all DCs are the same.

Transportation costs from the factory to all DCs are the same.

![]() Transportation/ handling costs from the DCs to the customers are adapted to the price level of the actual country.

Transportation/ handling costs from the DCs to the customers are adapted to the price level of the actual country.

![]() One year consists of two periods:

One year consists of two periods:

Summer period: 01.05.2021 - 31.10.2021

Demand coefficient: 1.2 (meaning 1.2 times higher demand as in winter due to higher demand during warm months)

Winter period: 01.11.2021 - 30.04.2022

Demand coefficient: 1.

![]() Orders are received every seven days (static demand).

Orders are received every seven days (static demand).

![]() Transportation speed is 80km/h, the capacity of a truck is 1,320 crates, which equals 33 pallets which are single stocked.

Transportation speed is 80km/h, the capacity of a truck is 1,320 crates, which equals 33 pallets which are single stocked.

![]() Price per crate for customer: $60.00.

Price per crate for customer: $60.00.

We assume that BERLIN BREWERY will sell 260,405 beer crates within the coming summer period (151,035 crates) and winter period (109,370 crates). Fig. 3 below shows the customers, according to the summer and winter periods. Substantial sales are made in Germany, especially in Berlin (32,807 beer crates per year) and the least sales are achieved in Basel, Switzerland (871 beer crates per year).

Figure 3: Distribution of sales by country and period, own illustration

The main customers are beverage retailers, which purvey to smaller retailers or restaurants. Therefore, it is considered that only one wholesaler is supplied per city. This wholesaler makes resales indepen- dently. As a result, no further storage costs are incurred as no further DC is required. Transportation to the wholesalers and handling is currently being handled entirely by a logistics service provider as BERLIN BREWERY does not yet have the necessary capacity and occupancy rate for profitable ship- ment. This service provider picks up the goods in the brewery, stores them in their own warehouse, and launches directly to the distributor as needed. The current financial performance is presented in Table 2.

Table 2: Current cost structure

2.3 Greenfield Analysis (GFA)

Now we conduct a GFA. The aim of this GFA is to determine optimal DC locations in the SC subject to minimum total transportation costs.

Creating an ALX model

Step 1. Open scenario BR GFA

Step 2. Check the tables Customers, DCs and Factories, Demand, Unit Conversions, and Products.

Performing experiments

Step 1. Go to GFA Experiment and run it for “Number of sites = 7” .

Step 2. Analyze the results using statistics “Product Flows”and “New Site Locations”. Step 3. Go to GFA Experiment and run it for “Number of sites = 2” .

Step 4. Analyze the results using statistics “Product Flows”and “New Site Locations”. Develop your managerial insights for the results with 7 and 2 DCs in terms of costs and responsiveness.

2.4 Network Optimization (NO)

The NO o↵ers the possibility of optimizing an existing SC according to maximum possible profit. In this case, the solutions of the GFA will be taken into account to optimize the SC. Having checked the suggested GFA sites for DCs, the SC manager of BERLIN BREWERY analysed those locations further regarding additional factors such as availability of warehouses to rent, construction costs for building new warehouses, fixed costs, infrastructure, future demand forecasts, etc. As a result, some of the GFA suggested locations are moved (Figure 4).

Figure 4: Alternative DCs locations

The NO goal is to find the SC design with the highest possible profit. To define the NO problem from a mathematical perspective, several parameters must be input as data. Each of the DCs has an inventory capacity of min. 5,800 beer crates and max. 11,600 beer crates. The brewery can stock 10,000 crates at maximum and should carry an inventory of at least 5,000 crates. Customers and their demands remain the same as in the GFA. To avoid confusion, the DCs are now marked as red icons. Green icons are added to symbolize the suppliers of beer ingredients. These suppliers are located in Nuremberg, Koblenz, and Dresden.

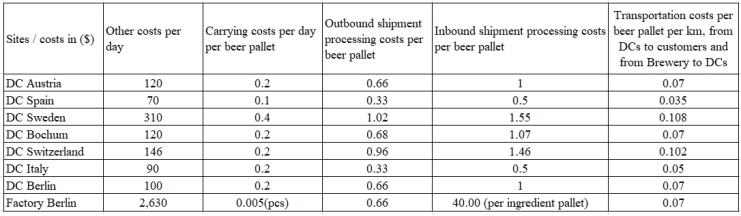

Figure 5 contains the costs of the sites. These numbers have been adjusted to the income ratios of each country. Two of them, Berlin and Bochum, are in Germany, and the overall prices in Berlin are cheaper than in western Germany.

Figure 5: Cost structure per site

Production costs at the brewery are $1.46. Revenue is $60.00.

Creating an ALX model

Step 1. Open scenario BR NO.

Step 2. Check data in tables “DCs and Factories”,“Facility Expenses”,“Paths”, “Processing Costs”, “Product Flows”, “Product Storages”,“Production”, “Products”, and “Vehicle Types”. Explain the data in the aforementioned tables. The data in these tables should correspond to Figure 5.

Performing experiments

Step 1. Step 1. Go to NO Experiment and run it.

Step 2. Analyze the results using statistics “Optimization Results”, “Flow Details”, “Production Flows”, “Demand”, and “Overall Stats”.

Given the threat of DC disruptions and the expansion plans with new customers, BERLIN BREWERY decides to redesign the SC by adding a second DC in Spain, which means that the fifth-best alternative is chosen out of 10 best SC designs displayed in “Optimization results”. The di↵erence in profit between the best and the fifth-best SC design is very small but the SC design with 2 DCs o↵ers more flexibility and resilience.

2.5 Simulation

Simulation can be used in many ways. It promotes understanding of how the SC will react in the event of disruptions, such as outages and/or external influences. To run di↵erent simulations, the outcome of the NO has been used. In the case of BERLIN BREWERY, a two-month disruption has been simulated to see what happens if only one DC is kept or if a second is rented in Spain. Di↵erences in, for example, the service level and profit could be decisive. For the simulation, assumptions must be made to make the model more realistic. The previous assumptions remain unchanged, and a lead time of five days is added. The sourcing policies are defined as follow: for the DCs, the program should choose the closest dynamic source. In this case, there is only one factory and the customers should choose the closest dynamic source to receive orders as soon as possible.

In simulation, we extend our analysis by adding the following features:

![]() We transit from flows (as in NO) to orders, i.e., the customer demand is no more considered as an aggregated flow during a period but it is now generated as orders in certain intervals, e.g., 10 crates per day.

We transit from flows (as in NO) to orders, i.e., the customer demand is no more considered as an aggregated flow during a period but it is now generated as orders in certain intervals, e.g., 10 crates per day.

![]() We introduce inventory control to manage ordering processes.

We introduce inventory control to manage ordering processes.

![]() We introduce sourcing policy (e.g., single vs. multiple sourcing) to manage replenishment processes.

We introduce sourcing policy (e.g., single vs. multiple sourcing) to manage replenishment processes.

![]() We introduce shipment control (LTL/FTL) to manage shipment processes.

We introduce shipment control (LTL/FTL) to manage shipment processes.

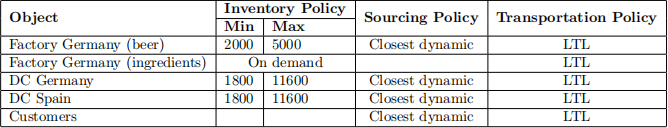

First, we simulate the SC with two DCs in Germany and Spain subject to the following data (Table 3).

Table 3: Parameters for simulation model

To evaluate the simulation results, we consider six KPIs according to the needs of BERLIN BREWERY:

1. Financial KPIs, such as profit, revenue and costs.

2. Service level by products, which is calculated as (number of outgoing orders / number of placed orders), where an outgoing order is an order that is not dropped.

3. Available inventory including backlog at DCs.

With all of the parameters described, we now run the simulations for a period of one year from May 1, 2021 until April 30, 2022.

Creating an ALX model

Step 1. Open scenario BR SIM

Step 2. Check data from Table 3 in tables “DCs and Factories”,“Inventory”, “Sourcing”, “Paths”, and“Shipping”. Explain the data in the aforementioned tables. The data in these tables should correspond to Table 3 and Figure 5.

Performing experiments

Step 1. Go to Simulation Experiment and run it.

Step 2. Analyze the results using the KPI Dashboard “Revenue, Profit, Costs”, “Service Level by Products”, ”Available Inventory including Backlog”.

2.6 Risk analysis: Two-month disruption at one of the DCs

This analysis simulates a two-month disruption of the DC in Berlin from August 1th to September 30th for two di↵erent network design scenarios, i.e., with two DCs and with a single DC in Berlin.

Creating an ALX model

Step 1. Open scenarios BR SIM Disruption Risk 2 DC and BR SIM Disruption Risk 1 DC. Step 2. Check data about the disruption in table “Events”.

Performing experiments

Step 1. Go to Simulation Experiment and run it.

Step 2. Analyze the results using the KPIs “Revenue, Profit, Costs”,“ Service Level by Products”, ”Available Inventory including Backlog”.

2.7 Comparison experiment

In order to simplify comparison of the two simulation scenarios subject to disruption with each other and with the“ideal”scenario (no disruption), we run a Comparison experiment.

Creating a Comparison Experiment

Step 1. Open scenario BR SIM and go to Comparison Experiment.

Step 2. Select scenarios BR SIM, BR SIM Disruption Risk 1 DC and BR SIM Disruption Risk 2 DC.

Step 3. Check KPI dashboard. The KPIs for a comparative analysis of the three scenarios should be “Available Inventory”, “Profit”, “Total Costs”and “Service Level by Products”.

Performing experiments

Step 1. Run Comparison experiment.

Step 2. Analyze the results using the KPIs “Available Inventory”, “Profit”, “Total Costs”and “Service Level by Products”.

2.8 Validation using Variation

Rather than running the same simulation multiple times with di↵erent parameter values or combinations, the variation experiment allows multiple variations of the same simulation to be run simultaneously. A variation experiment highlights how KPIs change depending on di↵erent parameter values. This kind of sensitivity analysis can also be used to verify the validity of the results of the simulation model.

A variation analysis will be now performed. The MIN parameter for the DCs will be varied with a minimum reorder point of 900 and a maximum reorder point of 2300 in steps of 200. The variation should be performed for a period of one year.

Creating a Variation Experiment

Step 1. Open scenario BR SIM and go to Variation Experiment.

Step 2. Check the parameter we will vary (i.e., Inventory Policy: DC for product beer: MIN).

Step 3. Check KPI dashboard. The KPIs for a variation analysis should be “Available inventory including Backlog”, “Profit”, and “Service Level by Products”.

Performing experiments

Step 1. Run Variation experiment.

Step 2. Analyze the results using the KPIs “Available Inventory including Backlog”, “Profit”, and “Service Level”.

2.9 Managerial Recommendations

Develop managerial recommendations for BERLIN BREWERY management. Consider GFA, NO, Simula- tion, Comparison, and Variation results. Which SC design would you recommend? Consider the impact of inventory control and disruptions. Are there any other relevant factors that should be taken into account besides the experiments performed? Make sure you consider the disadvantages (or negative elements) of the recommendations that you made. need reference

2.10 Important notes and helpful hints

![]() Do not enter/change data in the input scenario tables. Otherwise, you might get errors or wrong results when you run the experiments.

Do not enter/change data in the input scenario tables. Otherwise, you might get errors or wrong results when you run the experiments.

![]() In the assignment folder, there is a PDF file which can help you to avoid the potential mistakes and debug the errors if required.

In the assignment folder, there is a PDF file which can help you to avoid the potential mistakes and debug the errors if required.

![]() Follow the steps in each section for the experiments and write your own managerial insights after running the experiments and analysing the results. Do not repeat and write the steps in your report and just write the results of your analysis with corresponding figures, tables, etc. In analysing results you can also use other statistics, KPIs and output tables in ALX if you think it is necessary in addition to the aforementioned ones in di↵erent steps of the assignment.

Follow the steps in each section for the experiments and write your own managerial insights after running the experiments and analysing the results. Do not repeat and write the steps in your report and just write the results of your analysis with corresponding figures, tables, etc. In analysing results you can also use other statistics, KPIs and output tables in ALX if you think it is necessary in addition to the aforementioned ones in di↵erent steps of the assignment.

![]() Develop your own diagrams as much as you can (not just copy screenshots from ALX software), and provide some critical judgement on the results, and develop managerial insights.

Develop your own diagrams as much as you can (not just copy screenshots from ALX software), and provide some critical judgement on the results, and develop managerial insights.

![]() In answering the last section which is ”Managerial Recommendations”, group must use the results of running ALX software for previous sections of the assignment, and also examples of supply chain concepts, tools, techniques, and approaches to demonstrate strategies that can be used and using the literature to support assertions and recommendations.

In answering the last section which is ”Managerial Recommendations”, group must use the results of running ALX software for previous sections of the assignment, and also examples of supply chain concepts, tools, techniques, and approaches to demonstrate strategies that can be used and using the literature to support assertions and recommendations.

![]() The word limit( 4000-4500 words) is not a target that you need to reach – you can submit a shorter assignment. However, short assignments will probably not contain adequate discussions and analysis and may score poorly.

The word limit( 4000-4500 words) is not a target that you need to reach – you can submit a shorter assignment. However, short assignments will probably not contain adequate discussions and analysis and may score poorly.

![]() Where you are completing a ‘technical problem’ such as a network design problem, make sure that you commit the ‘technical’ part to an appendix while you retain the output and interpretation of the output in the main body of the report, referring the interested reader to the appendix for further details. In many cases, the appendix will rarely be considered; however, you will be surprised at the times when an executive will, in a sudden fit of curiosity, delve into the appendix and ask incisive questions about the minutiae contained therein.

Where you are completing a ‘technical problem’ such as a network design problem, make sure that you commit the ‘technical’ part to an appendix while you retain the output and interpretation of the output in the main body of the report, referring the interested reader to the appendix for further details. In many cases, the appendix will rarely be considered; however, you will be surprised at the times when an executive will, in a sudden fit of curiosity, delve into the appendix and ask incisive questions about the minutiae contained therein.

![]() No manager has all possible information before making a decision. Sometimes, crucial information is not obtainable or cannot be obtained on time or with suitable level of detail. Managers invariably find themselves dealing with grey areas when information is sparsely available or uncertain.

No manager has all possible information before making a decision. Sometimes, crucial information is not obtainable or cannot be obtained on time or with suitable level of detail. Managers invariably find themselves dealing with grey areas when information is sparsely available or uncertain.

![]() Do not get bogged down analysing numbers – focus on the key strategic, tactical, and operational issues that you can identify. The organisational strategy will influence their capacity, inventory, and other operational decisions in supply chain management. The numbers describe the detail but they are only a means to an end.

Do not get bogged down analysing numbers – focus on the key strategic, tactical, and operational issues that you can identify. The organisational strategy will influence their capacity, inventory, and other operational decisions in supply chain management. The numbers describe the detail but they are only a means to an end.

![]() Avoid using descriptive sentences and paragraphs – the readers of the report are extremely familiar with the organisation. Instead – be critical and provide insight. Constantly ask yourself ‘why’ they do what they are doing and ‘what if’ they change. Base these questions on what you learn in class.

Avoid using descriptive sentences and paragraphs – the readers of the report are extremely familiar with the organisation. Instead – be critical and provide insight. Constantly ask yourself ‘why’ they do what they are doing and ‘what if’ they change. Base these questions on what you learn in class.

![]() Be clear about who the audience of the report is. Who are the readers? In this case – senior manage- ment. Thus, your report should be written in a suitable style.

Be clear about who the audience of the report is. Who are the readers? In this case – senior manage- ment. Thus, your report should be written in a suitable style.

![]() You will need to balance the requirements/needs of each position/group member carefully. Conduct formal team meetings. Record minutes and include these as part of your submission (use an appendix). There should be evidence of discussions, disputes, and resolution of problems.

You will need to balance the requirements/needs of each position/group member carefully. Conduct formal team meetings. Record minutes and include these as part of your submission (use an appendix). There should be evidence of discussions, disputes, and resolution of problems.

![]() Supply chain concepts learnt in this unit must be linked to this assignment. Remember that this is an supply chain unit class; while concepts from other classes may be useful in your report your main focus and core discussions should focus on supply chain management.

Supply chain concepts learnt in this unit must be linked to this assignment. Remember that this is an supply chain unit class; while concepts from other classes may be useful in your report your main focus and core discussions should focus on supply chain management.

![]() One final point – make sure that you do not plagiarize from the case study or from other sources. The penalties are severe. Make sure you quote, paraphrase, and cite all materials and ideas appropriately.

One final point – make sure that you do not plagiarize from the case study or from other sources. The penalties are severe. Make sure you quote, paraphrase, and cite all materials and ideas appropriately.

2024-01-15