MSCI 222: OPTIMISATION COURSEWORK EXERCISE

Hello, dear friend, you can consult us at any time if you have any questions, add WeChat: daixieit

DEPARTMENT OF MANAGEMENT SCIENCE

MSCI 222: OPTIMISATION COURSEWORK EXERCISE

Coursework should be submitted online via Moodle by the date announced in Moodle.

The exercise is to be done individually. Late work or evidence of collusion will be penalised in the manner specified in the department's teaching code of practice.

Your answers should clearly state your reasoning and any assumptions you make.

You should define each variable you use in your models and summarise the reason for adding each constraint.

You should provide mathematical models and results(total cost and all flows) of your runs in your reports. You should also add the output files from the solvers (Lindo, Lingo, MS Excel or Python package) to the appendix of your reports. In addition to your report, you should also submit the separate solver input files, source codes or a single MS Excel file with one worksheet for each question to Moodle. If you answer all questions, you should submit a report and either a single MS Excel file with at least five worksheets (one for each question), or five additional solver input files or Python source codes (one for each question).

In the following problem, you should replace Y by the number between 0 and 99 formed by the 5th and 6th digits of your library card number, and Z by the number between 0 and 99 formed by the 7th and 8th digits of your library card number. For example, if your library card number is 08123456, then Y = 34 and Z = 56.

PART A (15 marks)

JeansGlobal, based in China, is a global supplier of denim jeans for apparel companies around the world. They purchase raw cotton from producers in Arkansas, Mississippi, and Texas, where it is picked, ginned, and baled and then transported by flatbed trucks to ports in Houston, New Orleans, Savannah, and Charleston, where it is loaded into containers and shipped to factories overseas. Then they are shipped to denim fabric plants located in Shanghai, Karachi and Saigon.

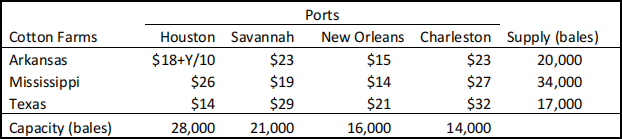

For the coming year, JeansGlobal has contracted with its U.S. broker for 71,000 (250 kg) bales of cotton and there is associated transportation and handling costs from each cotton-processing facility to each port. In addition, there is a handling capacity associated with each port. For instance, the total number of bales processed by the port in Houston cannot exceed 28,000. The transportation and handling cost from cotton farms to ports and each ports handling capacity are given as follows:

Table 1: Supply of cotton farms and capacities of ports (in bales) and the cost of sending one bale of cotton from each farm to each port (in US Dollars)

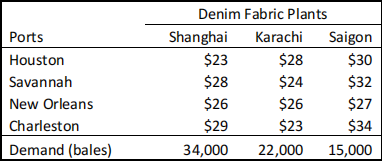

In addition, the shipping and handling cost per bale of cotton from each U.S. port to each of JeanGlobal’s overseas factories and the demand at these factories are as follows:

Table 2: Demand of denim fabric plants (in bales) and the cost of sending on bale from each port to each denim fabric plant (in US Dollars)

Determine an optimal shipment plan for the entire system that will result in the minimum total shipment cost by modelling this problem using a linear programming formulation and solving using an LP solver.

PART B (15 marks)

Second part of JeansGlobal’s operation include manufacturing denim fabric from bales (a bale of cotton will produce approximately 300 metres of denim fabric) and then sending them to denim jeans factories, producing jeans from denims and then sending them to distribution centres. JeansGlobal manufactures denim fabric at its factories in Shanghai, Karachi, and Saigon and ships it to its denim jeans manufacturing facilities in China, India, Japan, Turkey, and Italy and then send them to the distribution centres located in New York, Bristol, Marseilles and New Orleans.

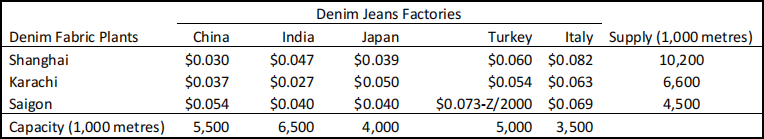

Following are the fabric demand at each denim jeans plant and the shipping and handling costs per 1000 metres from the fabric manufacturing facilities to the jeans plants:

Table 3: Supply from each denim fabric plants and the capacity of each denim jeans factories (in 1,000 metres) and the cost of sending one metres of denim from each denim fabric plants to denim jeans factories (in US Dollars)

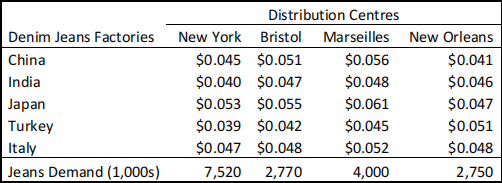

Each denim jeans require 1.25 metres of denim fabric. For instance, to produce 2,400,000 jeans, a denim jeans factory should receive 3,000,000 metres of denim fabric. Following are the contracted deliveries of jeans for each of JeansGlobal’s customer’s distribution centres, and the shipping and handling costs per jeans from the jeans factories to the distribution centres:

Table 4: Demand of each distribution centres (in 1,000s of jeans) and the cost of sending one jeans from each denim jeans factory to distribution centres (in US Dollars)

Determine an optimal shipment plan for the entire system that will result in the minimum total shipment cost by modelling this problem using a linear programming formulation and solving using an LP solver.

PART C (20 marks)

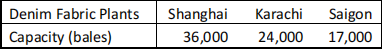

After solving the previous two problems and coming up with a total transportation cost, you have learned that the denim fabric plants have additional production capacities that can be used without investing any money on them. You think that considering the entire system with a single model instead of formulating it as two separate models can improve the cost associated with transporting cotton, bales, denim fabric and jeans. Write a single mathematical model that minimises the cost of transporting cotton, bales, denim fabric and jeans while satisfying the supply constraints of the cotton farms, demand constraints of the distribution centres and capacity constraints associated with the ports, denim fabric plants and denim jeans factories. Use the production capacity values for each denim fabric plants given below:

Table 5: Capacity of each denim fabric plant (in bales)

Determine an optimal shipment plan that will result in the minimum total shipment cost. Model this problem using a linear programming formulation and solve using an LP solver. Calculate the cost associated with your solution and present your solution in tabular form. Calculate also how much the company could save by including the transport decision from farms to distribution centres together.

PART D (20 marks)

After your analysis, JeansGlobal saved a significant amount of money in their usual operations. Recently, the company received a very lucrative deal that they need your help again. A rival company which is short of supplying their demand asked you to produce 1,44 million jeans for them. Within a short period, the company can invest only on one of their farms to increase cotton production to a level enough to satisfy this request (hint: you should first calculate how many metres of denim fabric needed to be manufactured, then calculate how many bales of cotton is needed to be produced to produce this much denim) and all the jeans produced for this company should be delivered to one of the distribution centres which will then be picked up by the rival company. The company wants to know which farm’s production capacity should be increased by how much and to which distribution centre the jeans ordered by the rival company should be delivered to minimise the total transportation, handling, and production cost of the entire system with the additional demand.

Determine an optimal shipment plan for the entire system that will result in the minimum total shipment cost by modelling this problem using a mixed integer linear programming formulation and solving using an LP solver. What is the additional transport cost of producing extra 1,44 million jeans. How much was the transport cost per jeans before increasing production and how much is it now after increasing production levels?

PART E (30 marks)

The deal with the rival company unfortunately has not gone through. The rival company found the price offered too high for them. However, this analysis also showed the vulnerabilities in the JeansGlobal’s supply-chain network and provided you a new problem to look at.

JeansGlobal wants to consolidate its supply operations where possible. They want to make sure every port can receive at least 80% of the cotton they receive from one and only one farm (each farm can still send different proportion of their produced cottons to different ports). As an example, port in Houston receiving 10,000 bales of cottons from both Arkansas and Texas is not a feasible solution since both farms cover only 50% of what Houston receives in total. On the other hand, if Houston receives 20,000 bales in total and Arkansas (or Texas, or Mississippi) sends at least 16,000 bales, since Houston receives at least 80% of their cotton from a single farm, it is a feasible solution (provided that all other constraints are also satisfied).

Determine an optimal shipment plan for the entire system with these new additional constraints that will result in the minimum total shipment cost by modelling this problem using a mixed integer linear programming formulation and solving using an LP solver. How much the cost changes when these new constraints are forced into the model?

2023-12-05