Biofluid Mechanics (BMEN90036) Assignment 1

Hello, dear friend, you can consult us at any time if you have any questions, add WeChat: daixieit

Assignment 1

The University of Melbourne

Instructions: Answer each of the following questions in a single document, containing any relevant workings. Please include appropriate figure axes labels in any plots. Equations may be handwritten. Attach (copy-paste) any code in an appendix in the same document.

Question 1 [30 marks]

To this point we have assumed that the height in tanks remains constant, which is appropriate for the case when we want to know the instantaneous flow rate for fluid moving between tanks. This is more complicated for analysing systems over longer timescales, however, when we want to know how the overall system evolves when the level in tanks change.

We want to fill a 0.5m diameter tank of a bioprocessing slurry (ρ = 1020 kg/m3 , µ = 0.0015 kg/ms) initially with a height of 2m to 6m using a pump operating with 82% mechanical efficiency and a brake power of 1500W if it is moving fluid from an immediately adjoining 1.5m diameter tank, initially filled to 2m. The pump and any entrance/exits to the tanks are located on the floor between the two tanks (at a height of 0m). The pump curve for this pump can be approximated by the equation hp = 20.2 – 0.02Q2 , where Q is the flow rate in m3 /h and hp has units of meters. Both tanks are vented to atmosphere. Because these tanks are so close together, you can ignore minor losses and friction effects from pipe tubing.

(Hint: you may not require all the values provided in the problem statement to calculate the answers to each of the following)

C. Following on from your answer to part (A), take the case where there is now a pipe (5 cm diameter, surface roughness of 0.03 mm) connecting Tank 1 to the pump, which we can assume has an NPSHR of 2.8m. The fluid has a vapour pressure of 4.2kPa. Ignore minor losses associated with entry and exit of pipes. Find the longest this pipe can be beforecavitation occurs at any point in the pumping process for the situation described, where the height in Tank 2 is to be raised to 6m high.

For simplicity, you can assume the pump head from the pump curve for the tank height at which cavitation is most likely to occur, though you should state whether this assumption will yield an overestimate or underestimate of the actual pipe length.[5 marks]

Question 2 [30 marks]

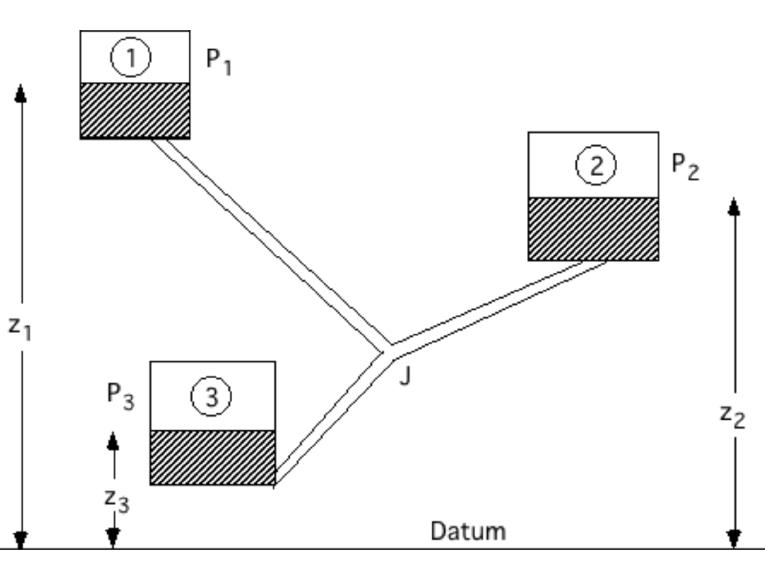

To date we have explored iterative solutions in class to calculate flow rates and pressures for complex systems. However, this process can be tedious to do by hand, especially for systems of increasing complexity, where a computational solution can help to arrive at the correct solution much faster. For the case of a pipe network shown below containing water (density = 1000 kg/m3 , viscosity = 0.001 kg/m3 ),

A. State the direction of the flow between each of the Tanks (1,2,3) and the junction – is the flow moving into or out of each of the tanks, and why? Draw a diagram showing the direction of flow. (Hint: you should be able to determine this without any iterative solution using the information provided). [5 marks]

the height of the free surface in Tank 3 is 25 m

Question 3 [15 marks]

A. What is the mass flow rate of the carbon dioxide? Show all working. [10 marks]

B. What is the maximum initial pressure that you would recommend in order to maximize the flow rate of carbon dioxide? Show all working. [5 marks]

Question 4 [25 marks]

2023-10-05