ME 360 Homework Assignment #3

Hello, dear friend, you can consult us at any time if you have any questions, add WeChat: daixieit

ME 360

Homework Assignment #3

Problem 1.

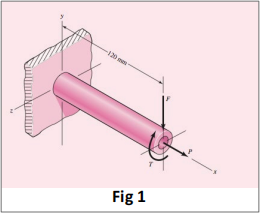

The cantilevered tube shown in Fig. 1 is to be made of 2014 Aluminum Alloy. We wish to select a stock-size tube from Table 1 (attached) using a 20 x 4 mm dimension and a design factor nd = 4. The bending load is F = 1.75 kN, the axial tension is P = 9.0 kN, and the torsion is T = 0 N · m.

Note the variable nd is the factor of safety using the distortion theory. We will talk about this later but for now you want to compute the von Mises stress, σ ′ , and compare that to the yield strength of the material.

Problem 2.

Create a SW finite element model of Problem 1.

a. Show images of the deformed configurations.

b. Include stress contour plots for the normal and shear stresses in the cross section near the location where you expect maximum stress.

c. Compare your solution for the maximum bending and shear stress using the percent difference.

d. Provide an engineering drawing using third angle view.

Make sure your solutions are clearly highlighted with a box or some other method to make them stand out.

Table 1: Properties of Round Tubing

2023-08-05