FIRE7660 STRUCTURAL FIRE ENGINEERING Assignment #1

Hello, dear friend, you can consult us at any time if you have any questions, add WeChat: daixieit

STRUCTURAL FIRE ENGINEERING (FIRE7660)

FIRE7660

Assignment #1

Comparison of analytical and Abaqus model

Introduction

This document describes Assignment #1. Please refer to the course Electronic Course Profile (ECP) for the submission deadline. Submission will be via Turnitin. Late submissions will not be accepted, unless exemptions have been approved by the course coordinator (see ECP for details).

Consider a steel beam with the following properties and cross-section.

• Section: 310 UB 40.4

(section dimensions shown in the figure to the right)

• Length: 10 [m]

• Modulus of Elasticity: 210,000 [MPa]

• Coefficient of Thermal Expansion, α : 11 x 10-6 [K- 1]

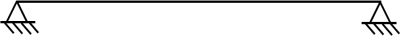

Assume the boundary conditions to be pinned, i.e. restrained both axially and vertically according to Figure 1, below.

Figure 1. beam with pinned boundary conditions

Task 1 (15pts)

Analyse the beam using the analytical calculation methods shown during the lectures (Reccommended Lecture #1 - Usmani et al. 2001). Calculate the (1) axial force and (2) moment at mid-span and (3) mid-span deflection for three different cases of average temperature increase and through-depth temperature gradient, as described in the table 1 shown below.

Ignore the weight of the beam and state any assumptions you might have to make. If you calculate a critical buckling temperature, state if the assumptions made are conservative or non-conservative.

Task 2 (25pts)

Analyse the beam using ABAQUS with three different cases of average temperature increase and through-depth temperature gradient, as described in the table 1 shown below. For each of the three cases, plot (1) axial force, (2) moment at mid-span, and (3) mid- span deflection against temperature; between ambient and final temperature increase. Also, describe the response of the beam and verify that the Abaqus results are giving an appropriate response based on the theory presented during the lectures.

Table 1. Temperature cases to consider

|

Average temperature increase |

Through-depth gradient |

|

530 。C |

0 。C/mm |

|

530 。C |

3 。C/mm |

|

530 。C |

8 。C/mm |

Task 3 (60pts – 6 pts per subtask)

Using theory shown in lectures/tutorials and/or performing further caculations (analytical and/or using Abaqus), explain (using text, equations, and/or diagrams) the influence of the following variations in the calculation for the beam’s (1) axial force, (2) mid-span deflection, and (3) moment at mid-span.

|

Task 3.1 |

Assume that there is no external loads acting on the beam. |

|

Task 3.2 |

Increase of the beam’s web thickness from 6.1 [mm] to 10.2 [mm]. |

|

Task 3.3 |

Increase of the beam’s flange thickness from 10.2 [mm] to 20.4 [mm], while the beam’s depth remains at 304 [mm]. |

|

Task 3.4 |

Reduction of the beam’s depth from 304 [mm] to 152 [mm]. |

|

Task 3.5 |

Reduction of the beam’s length from 10 [m] to 6.5 [m]. |

|

Task 3.6 |

Increase of the Modulus of Elasticity from 210,000 [MPa] to 300,000 [MPa]. |

|

Task 3.7 |

Increase of the Coefficient of Thermal Expansion from 11 x 10-6 [K-1] to 11 x 10-5 [K-1]. |

|

Task 3.8 |

Change of the boundary conditions at one end, replaced with a condition free to translate horizontally (i.e. a pinned roller). |

|

Task 3.9 |

Change of the boundary conditions at one end, replaced with a condition free to translate horizontally and with an horizontal spring condition with a stiffness 80,000 [N/mm]. |

|

Task 3.10 |

Change of the boundary conditions at one end, replaced with a condition free to translate horizontally and with an rotational spring condition with a stiffness 40,000 [Nmm/rad]. |

2023-03-27

Comparison of analytical and Abaqus model